-

-

1956 Acquisition of license to manufacture batch mills

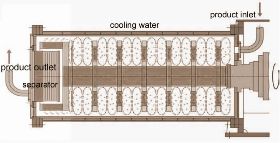

A special agitator shaft with symmetrically arranged agitator pegs and sleeves of tungsten carbide for wear protection devel- Vertical, batch operation mill for the preparation of tungsten Ideal flow behaviour due to a special agitator peg arrange-ment and the hemispherically shaped chamber floor integrated screen plate for grinding media separationIntensive cooling through a double-wall grinding tank and cooled circulation pipeline

-

-

Development of the first continuous agitator bead mill

Product inlet via rotor / immersion tube system prevents back flow of grinding media into the feed line.

-

-

Bottom up & Top down

Generally, there are two ways to obtain nano-powders. A bottom-up manufacturing method (bottom up) for chemical methods, such as chemical precipitation, sol-gel process (sol-gel),... Another method is physical method, which changes the powder particles from big to small (top down), such as mechanical ball milling,... And so on.

-

-

Horizontal Disk Grinding Machines

The Development In 1963, the first vertical agitator was developed internationally, the first horizontal agitator was developed in 1975, the first horizontal agitator bead mill with eccentric disks was introduced to the public and the horizontal disc grinder was introduced, in 2004, which became the industry standard. In the following years, the grinding media separation systems, the geometry of the grinding disks and the various grinding chamber materials were further developed.

-

-

Rod-pin nano-grinding Technology

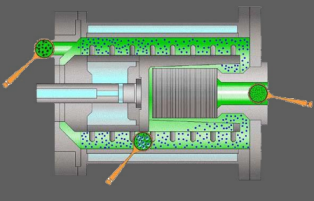

The grinding system pin nanomill shows the evolutionary develop- ment of system with the rotor-slotted pipe separating system. The enclosed horizontal agitator mill is designed for highest product throughput rates and possesses a pin grinding system for highest grinding intensity.

-

-

Ceramic comminution chamber technology

In 2011, we developed the first zirconia comminution chamber technology in China. It has no metal ion pollution and is used in batteries, pharmaceuticals, glazes, ink and food.

180ml粉碎腔,單批次物料只需最少150ml,清洗簡單,可以小批量實驗配方,物料罐位于研磨筒上方,儲料罐可自由放大,批量為150-800ml,短連接管線。材質耐磨95%釔穩定氧化鋯等,同時可選擇無壓高密度碳化硅耐磨陶瓷,..

180ml粉碎腔,單批次物料只需最少150ml,清洗簡單,可以小批量實驗配方,物料罐位于研磨筒上方,儲料罐可自由放大,批量為150-800ml,短連接管線。材質耐磨95%釔穩定氧化鋯等,同時可選擇無壓高密度碳化硅耐磨陶瓷,.. 采用雙端面機械陶瓷合金密封,使用壽命長,棒銷式結構,可以用較小的研磨鋯球,是實驗配方的理想之選。

采用雙端面機械陶瓷合金密封,使用壽命長,棒銷式結構,可以用較小的研磨鋯球,是實驗配方的理想之選。 NORVA諾研NNM05L實驗棒銷循環研磨機式基于實驗室平臺開發的,采用了模塊化設計,具有非常優秀的操作靈活性,其核心部件為“特耐磨鋼研磨腔、氧化鋯陶瓷、碳化硅陶瓷研磨腔和聚氨酯PU腔”,新型轉子結構,效率提升了3..

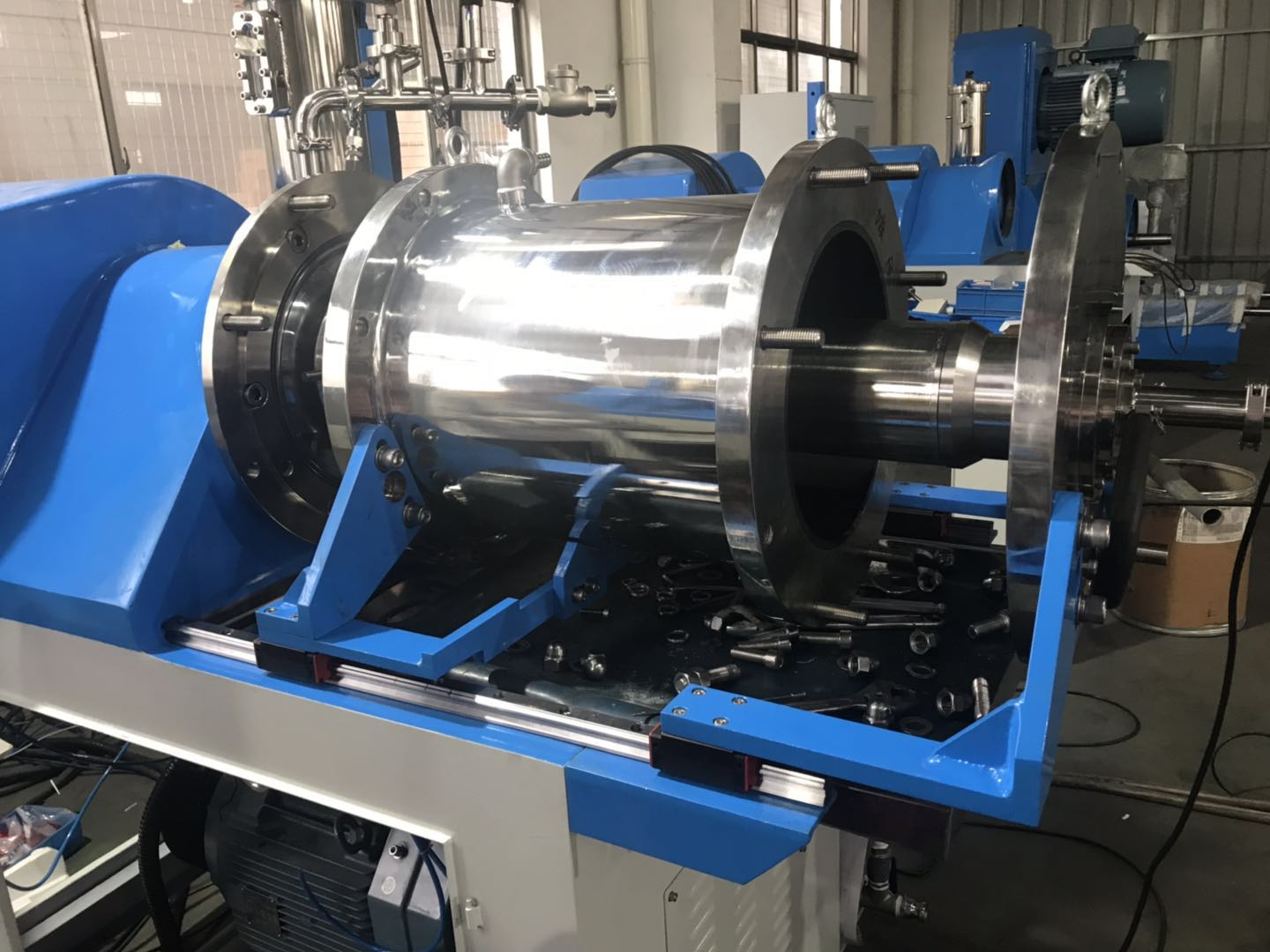

NORVA諾研NNM05L實驗棒銷循環研磨機式基于實驗室平臺開發的,采用了模塊化設計,具有非常優秀的操作靈活性,其核心部件為“特耐磨鋼研磨腔、氧化鋯陶瓷、碳化硅陶瓷研磨腔和聚氨酯PU腔”,新型轉子結構,效率提升了3.. NORVA諾研NMZ系列棒銷式納米砂磨生產用途非常廣泛。轉子采用棒銷設計,安裝在攪拌軸上,攪拌軸可以帶動整個研磨筒里的研磨介質旋轉,動態高效離器系統可很好地分離產品和研磨介質。帶有強冷卻的雙面機械密封,運行可..

NORVA諾研NMZ系列棒銷式納米砂磨生產用途非常廣泛。轉子采用棒銷設計,安裝在攪拌軸上,攪拌軸可以帶動整個研磨筒里的研磨介質旋轉,動態高效離器系統可很好地分離產品和研磨介質。帶有強冷卻的雙面機械密封,運行可.. NORVA諾研NMZ系列棒銷式砂磨生產用途非常廣泛。轉子采用銷棒設計,安裝在攪拌軸上,攪拌軸可以帶動整個研磨筒里的研磨介質旋轉,動態高效離器系統可很好地分離產品和研磨介質。帶有強冷卻的雙面機械密封,運行可靠,..

NORVA諾研NMZ系列棒銷式砂磨生產用途非常廣泛。轉子采用銷棒設計,安裝在攪拌軸上,攪拌軸可以帶動整個研磨筒里的研磨介質旋轉,動態高效離器系統可很好地分離產品和研磨介質。帶有強冷卻的雙面機械密封,運行可靠,.. NORVA諾研籃式砂磨機研磨籃采用封閉式設計,研磨介質裝于籃內,避免了傳統砂磨機研磨介質和物流混裝的方式,由研磨籃的高速旋轉形成高速線速度,使物料形成良好的研磨,分離系統采用了縫柵式分離器,縫隙范圍為0.3-1..

NORVA諾研籃式砂磨機研磨籃采用封閉式設計,研磨介質裝于籃內,避免了傳統砂磨機研磨介質和物流混裝的方式,由研磨籃的高速旋轉形成高速線速度,使物料形成良好的研磨,分離系統采用了縫柵式分離器,縫隙范圍為0.3-1.. NORVA諾研臥式納米砂磨機是一款真正的研磨至納米級范圍內的高端研磨機器,采用先進的銷棒研磨體系設計,轉子外表面安裝了大量耐磨鋼材質的棒銷,與定子形成了研磨腔,轉子旋轉形成強大研磨渦流撞擊和剪切力,將物料..

NORVA諾研臥式納米砂磨機是一款真正的研磨至納米級范圍內的高端研磨機器,采用先進的銷棒研磨體系設計,轉子外表面安裝了大量耐磨鋼材質的棒銷,與定子形成了研磨腔,轉子旋轉形成強大研磨渦流撞擊和剪切力,將物料.. NORVA諾研NH系列Disk盤式砂磨生產用途非常廣泛。轉子采用偏心盤設計,安裝在攪拌軸上,攪拌軸可以帶動整個研磨筒里的研磨介質旋轉,動態高效離器系統可很好地分離產品和研磨介質。帶有強冷卻的雙面機械密封,運行可..

NORVA諾研NH系列Disk盤式砂磨生產用途非常廣泛。轉子采用偏心盤設計,安裝在攪拌軸上,攪拌軸可以帶動整個研磨筒里的研磨介質旋轉,動態高效離器系統可很好地分離產品和研磨介質。帶有強冷卻的雙面機械密封,運行可.. NORVA諾研臥式納米砂磨機是一款真正的研磨至納米級范圍內的高端研磨機器,采用先進的銷棒研磨體系設計,轉子外表面安裝了大量耐磨鋼材質的棒銷,與定子形成了研磨腔,轉子旋轉形成強大研磨渦流撞擊和剪切力,將物料..

NORVA諾研臥式納米砂磨機是一款真正的研磨至納米級范圍內的高端研磨機器,采用先進的銷棒研磨體系設計,轉子外表面安裝了大量耐磨鋼材質的棒銷,與定子形成了研磨腔,轉子旋轉形成強大研磨渦流撞擊和剪切力,將物料.. Visit Us:

Visit Us: