-

-

1956 Acquisition of license to manufacture batch mills

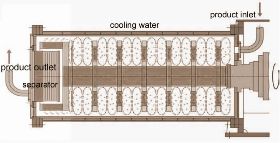

A special agitator shaft with symmetrically arranged agitator pegs and sleeves of tungsten carbide for wear protection devel- Vertical, batch operation mill for the preparation of tungsten Ideal flow behaviour due to a special agitator peg arrange-ment and the hemispherically shaped chamber floor integrated screen plate for grinding media separationIntensive cooling through a double-wall grinding tank and cooled circulation pipeline

-

-

Development of the first continuous agitator bead mill

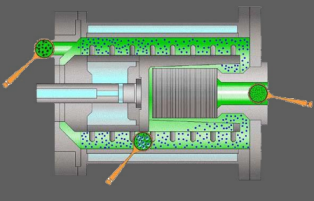

Product inlet via rotor / immersion tube system prevents back flow of grinding media into the feed line.

-

-

Bottom up & Top down

Generally, there are two ways to obtain nano-powders. A bottom-up manufacturing method (bottom up) for chemical methods, such as chemical precipitation, sol-gel process (sol-gel),... Another method is physical method, which changes the powder particles from big to small (top down), such as mechanical ball milling,... And so on.

-

-

Horizontal Disk Grinding Machines

The Development In 1963, the first vertical agitator was developed internationally, the first horizontal agitator was developed in 1975, the first horizontal agitator bead mill with eccentric disks was introduced to the public and the horizontal disc grinder was introduced, in 2004, which became the industry standard. In the following years, the grinding media separation systems, the geometry of the grinding disks and the various grinding chamber materials were further developed.

-

-

Rod-pin nano-grinding Technology

The grinding system pin nanomill shows the evolutionary develop- ment of system with the rotor-slotted pipe separating system. The enclosed horizontal agitator mill is designed for highest product throughput rates and possesses a pin grinding system for highest grinding intensity.

-

-

Ceramic comminution chamber technology

In 2011, we developed the first zirconia comminution chamber technology in China. It has no metal ion pollution and is used in batteries, pharmaceuticals, glazes, ink and food.

Visit Us:

Visit Us: